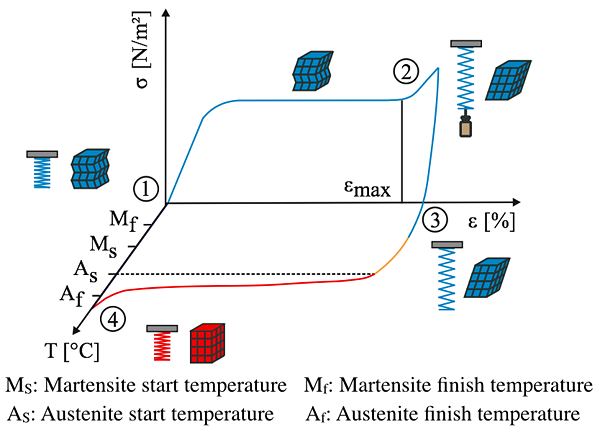

Thermal shape memory effect

Shape Memory Alloys (SMA) are able to return to their original shape on heating even after large deformation of up to 10% (thermal shape memory effect). This effect is illustrated in the stress-strain-temperature diagram. By mechanical loading using a weight, the SMA spring is deformed to a large extent (1→2). This pseudo-plastic deformation is enabled by reorientation of crystallographic variants in the cold temperature phase (martensite). In martensitic state, no energetic preference exists among the differently oriented crystallographic variants and, therefore, this state is metastable. Consequently, the deformation persists after load removal (2→3). On heating, the material undergoes a phase transformation to austenite. Because of the cubic crystal structure only one crystallographic variant exists in austenite state and, thus, only one possible shape that can be taken on heating (3→4). During shape recovery, large strain changes and large forces occur that are of special advantage for the development of microactuators.

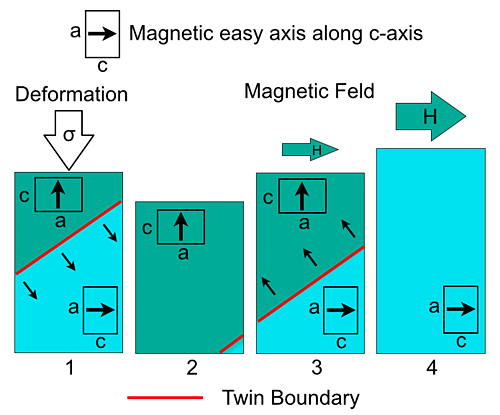

Magnetic shape memory effect

Magnetic SMAs are able to return to their original shape even after large deformation of up to 12%, by applying an external magnetic field (magnetic shape memory effect). The underlying mechanism is illustrated in the schematic for the tetragonal structure of a Ni-Mn-Ga single crystal in martensite state. By applying a pressure, the crystallographic variants are oriented such that the short c-axes are aligned along the force direction (1). This state is metastable and persists after releasing the force (2). Because of magnetic anisotropy the magnetic moments are aligned along the c-axis. On applying an external magnetic field perpendicular to the c-axis, magnetic moments and corresponding c-axis being coupled with each other reorient in field direction. This field-induced reorientation of martensite variants occurs by a movement of twin boundaries through the material (3) until all c-axes are aligned in field direction (4). This process may happen within less than 1 ms in contrast to the thermal shape memory effect.

|

A short introduction to the shape memory effect and demonstration of this effect for a spiral coil microactuator of NiTi lifting a weight hundred times larger than its own weight. Download video: MP4 format, 13.2 MB |