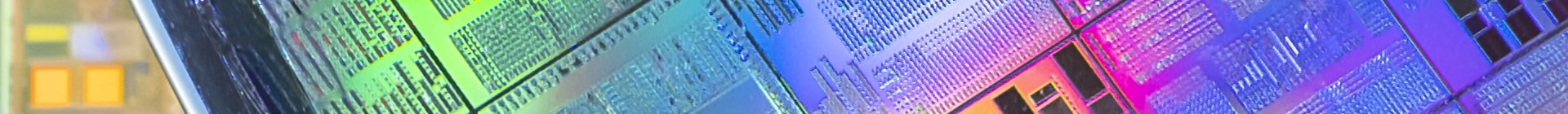

Cleanroom

The central facility of the Institute of Microstructure Technology is its cleanroom with a total floor area of approximately 600 m² and with cleanliness levels ranging from ISO classes 7 to 2. The cleanroom is especially designed for manufacturing and inspection of micro and nanostructures. It is equipped for

- lithography (e.g. Electron Beam Lithography, Direct Laser Writing, 2-Photon Lithography and UV Lithography)

- the respective pre- and post-processing (e.g. wet etching, dry etching, spincoating, CVD, PVD, electroplating) as well as for

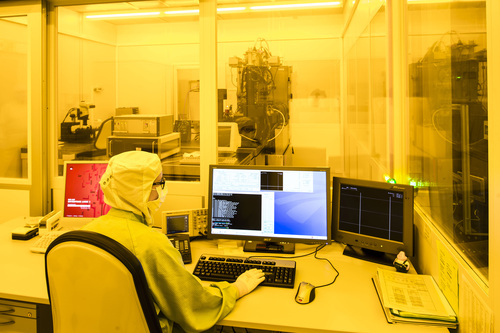

- characterisation methods (e.g. SEM with EDX, profilometer, ellipsometer, optical microscopes).

The cleanroom is open for students, Ph.D. candidates and staff members mainly affiliated to IMT to execute their research and development projects. The cleanroom and the equipment are run by scientists, engineers, technicians and laboratory assistants. The equipment is operated in two ways: according to hands-on principles as well as by an expert-based service, depending on both the complexity of machines and processes and on the education and experience of users.

|

Yellow-light cleanroom of IMT: operator |

Test laboratory: Scanning Electron Microscope |

|

|

Dr. Köhler (back row, first from right) and his core team in front of the cleanroom (Photo: Breig, KIT). |

Atomic Layer Deposition of e.g. SiO2, Al2O3 and TiO2 (Photo: Breig, KIT). |