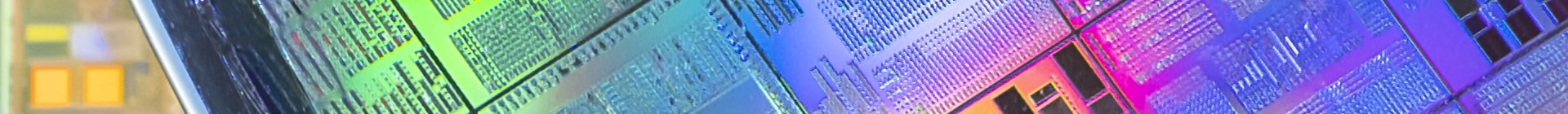

Surface Structuring

For polymer surface structuring by replication the processes hot embossing, nanoimprint, thermoforming and roll-to-roll replication are available. In our labs we operate these machines under clean room and/or temperature controlled conditions. Each Machine is optimized for selected tasks so we can adapt processes and technique for a large diversity of requirements regarding structure size, structured area, temperature and materials.

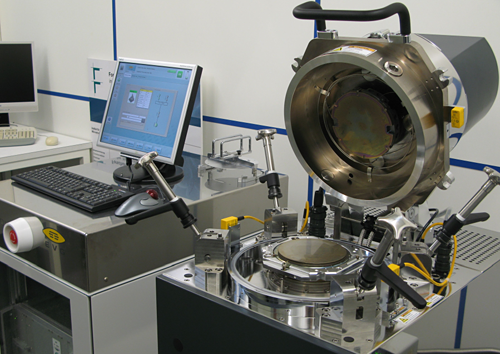

Roll-To-Roll Replication

- Laboratory roll-to-roll system – optimized for different tasks

- Force controlled and position controlled

- Roll diameter: 150mm, width 300mm

- Roll heating and preheating system

- Optimized mounting unit for fixation of microstructured shims

- Mounting unit for steel sleeves for seamless replication of microstructures