Dry Etching Cluster

Our Dry Etching Cluster consists of the Oxford RIE Plasmalab System 100 with ICP 380 source and the Oxford RIBE Ionfab 300. (RIE: Reactive Ion Etching, ICP: Inductively Coupled Plasma, RIBE: Reactive Ion Beam Etching). The Dry Etching Cluster is an advanced tool for micro- and nanomachining of various materials. The basic feature is a high frequency generator (RF) working at 13.56 Mhz, combined with a high vacuum chamber for wafers with a diameter of 4”. The power varies in the range of 1-2500 W. The gases used in our Dry Etching Cluster are among others SF6, CHF3, Cl2, BCl3 and HBr, allowing the structuring of a large variety of materials. For very shallow silicon designs in the nm range HBr is the preferred gas. Finally, for metal layer systems different Cl- und F-based RIE processes are available. Key features are:

- Silicon etching via the cryo process (process temperatures are between -80 and -150 °C)

- Production of highly vertical, highly parallel and smooth sidewalls

- Critical lateral dimensions down to the range of 100 nm

- Aspect ratios (ARs) up to 6 are possible.

- Laser end point detection

- Metal etching via RIBE

The Dry Etching Cluster belongs to the KNMFi equipment. External users can apply for machine time by means of a proposal system at www.knmf.kit.edu.

Overview of the RIE/RIBE Cluster (Oxford Plasmalab RIE100-ICP380, Oxford Ionfab 3000Plus)

|

|

|

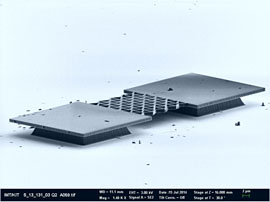

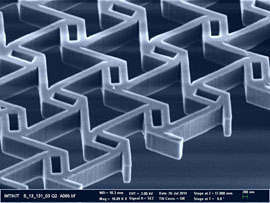

| Auxetic bridge etched in silicon by DRIE (Silicon Cryo Process) with underetched oxide layer. Thickness of the silicon device: 1µm; width of the auxetic bars: approx. 300 nm. | Detail of a chiral auxetic structure (fabrication and dimensions see figure left). Application: exploration of the mechanical properties of in vivo growing cells. |