Magnetic Levitation

(Dr. Vlad Badilita, Dr. Kirill Poletkin)

Hybrid Micromachined Contactless Suspension

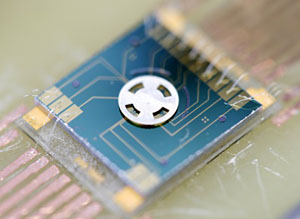

In a hybrid micromachined contactless suspension prototype, which combines electromagnetic inductive and electrostatic actuation, we have demonstrated an increase in operational capabilities such as dynamical adjustment of stiffness components, linear and angular positioning, as well as bistable actuation of the levitated proof mass.

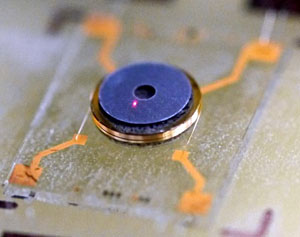

Figure 1a shows the proof mass being levitated on top of the hybrid suspension structure. The electrodes for electrostatic adjustment are visible on the top wafer. Figure 1b shows a cross-section through the device with the wirebonded microcoils providing the stable levitation and the top wafer with electrodes for electrostatic actuation.

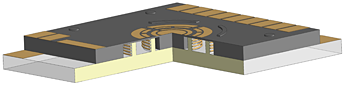

Figure 1: (a) Prototype of a hybrid micromachined inductive suspension. The electrodes for electrostatic actuation and the levitated proof mass are shown; (b) Schematic of the hybrid micromachined inductive suspension showing the 3D wirebonded coils for levitation and the top electrodes for electrostatic actuation.

Micro-transporter

Eliminating, by means of levitation, the mechanical attachment in moving parts of a micro-actuator leads to a significant increase in the range of linear and angular motions, therefore considerably more freedom in manipulating the corresponding proof mass. This opportunity can be naturally used in the transportation of the micro-object within a micro-system, as shown in Figure 2 by means of combining electromagnetic inductive levitation and electrostatic linear propulsion of the micro-object.

Figure 2: Transportation prototype showing the levitated micro-object and the electrodes for linear propulsion

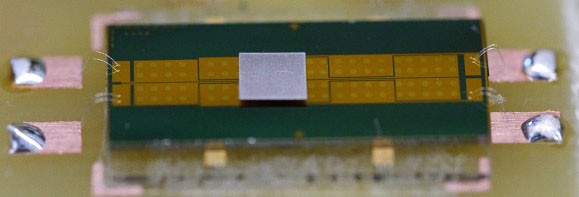

3D Micromachined Inductive Contactless Suspension with the lowest operating temperature

A newly developed polymer magnetic composite with high resistivity and high permeability has been employed as a magnetic core to significantly improve the energy consumption of the micromachined inductive suspensions. This brings the operating temperature down from 120°C to 60°C at room temperature operation, being the lowest value among all previously reported micromachined inductive suspensions prototypes.

Figure 3: Micromachined inductive suspension with the levitation coils filled

with the polymer magnetic composite for improved energy performance.

Further Information: