IMT is a world leader in research at the intersection of application-oriented materials development, the information sciences, and energy. R&D at the institute focuses on techniques for functional materials discovery, based on innovative concepts for magnetic resonance and x-ray analysis. Our nanotechnological basis drives R&D in nanoscale effects, for spin dynamics, optics, photonics, and photovoltaics.

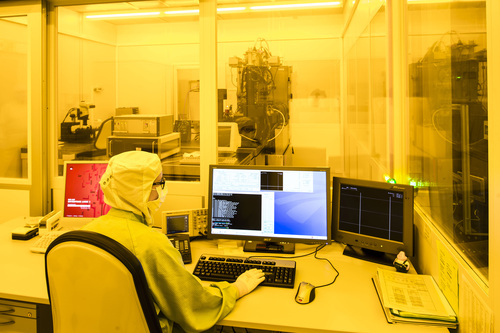

Our research topics all draw on the wide range of microstructuring and characterisation techniques that we both develop and operate in our numerous dedicated laboratories and clean rooms.

We extensively educate M.Sc. and Ph.D. thesis students, and our alumni hold key positions at the top technology addresses worldwide, in both industry and academia.

KIT Infrastructures managed by IMT

The Karlsruhe Nano Micro (KNMFi) (image video) offers a dedicated set of state-of-the-art technologies for structuring and characterizing a multitude of functional materials at the micro- and nanoscale.

more

The Karlsruhe Centre of Optics & Photonics (KCOP) is supposed to enable the framework conditions for excellent research in Energy and Resource Efficiency, Communications and Connectivity, Information Acquisition in Life Sciences, Information Acquisition in Industry and Research, Quantum Technologies and Quantum Sensors and Digital Nano-Fabrication & Tailored Materials – not only for members of the KIT!

More

The Karlsruhe nuclear magnetic resonance facility (KNMR) (image video) will be a research infrastructure embedded in KIT in which leading PIs are pioneering NMR research, and will be open to internal and external user research groups dedicated to equipment development and augmentation, method development, and experimental application in academic and industrial research.

More

The Karlsruhe Institute of Technology (KIT) has been successful with two approved proposals in the final of the Clusters of Excellence funding line that is part of the Excellence Strategy competition of the Federation and the States.

IMT is actively involved in the cluster 3D Matter Made to Order (3DMM2O). 3D printing technology makes it possible to turn digital blueprints into reality. With this kind of shaping, material is locally added instead of being removed. Scalable 3D printing using a wide range of inorganic, organic, biobased, and hybrid materials has developed into a powerful tool for the life and engineering sciences.

KIT press release

The Karlsruhe Nuclear Magnetic Resonance facility (KNMR) is planned as a new and comprehensive magnetic resonance centre for materials science, situated at KIT. KNMR will host the next generation magnetic resonance instrumentation, enabling materials scientists and chemical engineers unprecedented characterisation capabilities. It will additionally serve as a hub for novel magnetic resonance engineering, further pushing technological boundaries and enabling new measurement modalities.

The KNMR project is submitted by KIT to the BMBF's (Bundesministerium für Bildung und Forschung) Large Research Infrastructure program.

More information about KNMR

Researchers at the Light Technology Institute (LTI) and the Institute of Microstructure Technology (IMT), in collaboration with Helmholtz AI, are advancing the scalable fabrication of perovskite solar cells using deep learning. Reproducibility and consistent quality remain key challenges in scaling up perovskite solar cell production. In their latest work, Felix Laufer, Markus Götz, and Ulrich W. Paetzold show how deep learning allows material composition monitoring, enables early prediction of device performance, and provides data-driven process control recommendations for optimal fabrication outcomes. The study highlights the transformative role of AI in accelerating the path to commercialization for perovskite photovoltaics.

KIT press release

Jingyuan Xu is featured in the Women@KIT video series as the Head of the ZEco Thermal Lab, showcasing her research group and personal career journey. This video is part of the highlights of KIT’s 200-year anniversary celebrations.

Link to video

With five award winners, the IMT was extremely successful at the KIT President's Evening of Honour: Dr. S. Lehmkuhl becomes a Emmy-Noether fellow, Prof. U.W. Paetzold acquired an ERC-Consolidator Grant, Dr. J. Xu got a Nexus-funding from Carl-Zeiss Stiftung to build up a young investigator group, Dr. G. Huang was honored with the IU35 award as most brilliant innovator under 35 and Dr. J. Joseph received the HGF doctoral award for his excellent PhD thesis.

Prof. J. Korvink and Dr. D. Buyens from IMT together with Dr. S. Wadhwa from spin-off Voxalytic GmbH have developed a pioneering method with which, for the first time, the chiral structure of a molecule - the exact spatial arrangement of the atoms - can be elucidated directly using nuclear magnetic resonance spectroscopy. This important step in the development of new drugs has previously been a time-consuming process. Now the new method could become a standard tool for the chemical and pharmaceutical industries. The results were published in the high impact factor journal Advanced Materials.

Link to publication