Dr. Vlad Badilita

Karlsruhe Institute of Technology

Institute of Microstructure Technology

P.O. Box 3640

76021 Karlsruhe

phone: +49 721 608-29315

e-mail: vlad badilita∂kit edu

Electronics and electrical engineering, mechatronics, mechanical engineering

Nuclear Magnetic Resonance (NMR) is a characterization/investigation method that provides exquisite information about the chemical composition of a sample. NMR is closely related to another method that is more widely known due to the fact that it is broadly used in hospitals for clinical investigation in humans – magnetic resonance imaging (MRI). Both methods share the same physical principles and similar challenges.

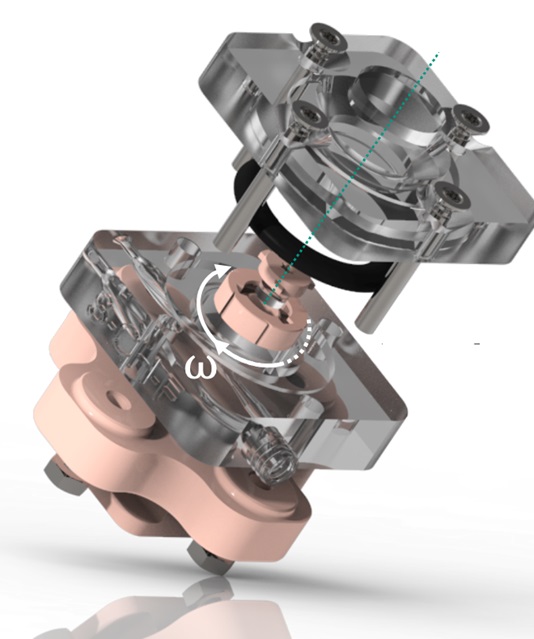

One of the fundamental components of solid state NMR equipment is the probe that holds and spins the sample at speeds beyond 1 kHz through pneumatic actuation. The probe has to be designed and manufactured in such a way that it should be able to (i) precisely set the angular position of the sample inside the equipment, and (ii) actuate it at the desired rotational speed with a variation of no more than ∓ 1 Hz. These ambitious design goals need to be tested after the manufacturing of the probe using 3D printing technology. These are tasks that require good mechanical and electrical engineering background to address challenges such as implementing an angular positioning mechanism to yield ∓0.1° and accurately measuring the rotational speed down to ∓ 0.1 Hz.

Are you passionate about mechanical design and manufacturing? Are you enthusiastic about microelectronics and automation? Are you ready to challenge yourself to build and test such a robust probe that can be used in future NMR equipment? If the answer is “yes”, we are looking for you!

The specific tasks within the project will be: (i) designing mechanical components for the probe head; (ii) fabrication of the individual components with 3D printing; (iii) establishing a test setup involving electrical signal acquisition and processing devices to measure the rotational speed. During the Master thesis, you will acquire hands-on experience on mechanical and electronics design as well as 3D printing. In addition, you will have opportunities to get exposure to a wide range of instruments and techniques.

You will be integrated in the larger team of the Spin & Photon Applications (SPA-) Laboratory. Within this project, you will use the infrastructure existent at the Institute of Microstructure Technology (IMT), i.e., microfabrication facilities, RF testing equipment, and multiple state of the art NMR scanners. This is a complete project, offering the possibility to fabricate and test the devices, giving you the opportunity to co-author conference and/or journal publications.

Contract's Duration: 6-9 Months Entry Date: by Appointment

click here for more information and online apply

Dr. Vlad Badilita

Karlsruhe Institute of Technology

Institute of Microstructure Technology

P.O. Box 3640

76021 Karlsruhe

phone: +49 721 608-29315

e-mail: vlad badilita∂kit edu