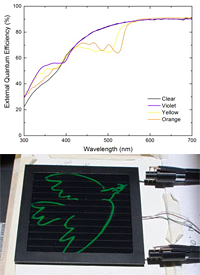

We have shown that the poor short-wavelength response of nearly all PV technologies can be improved via luminescent down-shifting (LDS) of high energy photons in sunlight. This is shown for silicon PV in the top Figure. In addition, the use of luminescent materials results in colouration of PV modules, a property that is of particular focus for applications where aesthetics are important, such as building-integrated PV (BIPV). At IMT we develop materials for LDS and the methodology to integrate LDS layers to PV modules. The bottom Figure shows the potential of LDS for graphical designing of PV modules, which is another direction we are pursuing using inkjet printing.

Contact: I. Howard

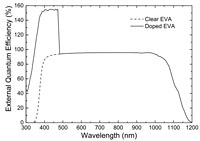

Down-Conversion (DC) otherwise known as quantum-cutting of a high energy photon to two lower energy photons can lead to significant gain in PV module efficiency. The in-principle potential of the DC technology to result in external quantum efficiency (EQE) values in excess of 100% is shown in the Figure. At IMT we target this technology using suitable lanthanide ion pairs embedded in thin-films that can be integrated in the PV module architecture.

Contact: I. Howard, A. Turshatov

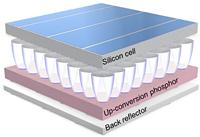

PV modules are transparent to photons with lower energy than the semiconductor’s bandgap. At IMT we develop materials that can perform up-conversion (UC) with high efficiency and the methodology to integrate UC layers to PV modules.

Contact: I. Howard, A. Turshatov

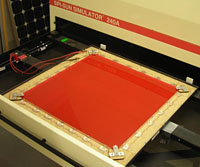

The luminescent solar concentrator (LSC) is a low concentration technology that has the potential to lower the cost of solar electricity by using inexpensive materials. The Figure at the left shows a large-area (60 cm x 60 cm) LSC in a flash solar simulator for electrical characterization. The LSC is a particularly promising technology for the urban environment, as it offers a great degree of flexibility in shape, colour and system design. At IMT we investigate ways to increase the LSC efficiency and upscale the technology.

Contact: I. Howard

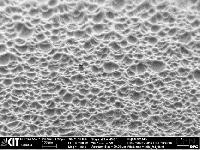

Nano- and micro-structured super-hydrophobic layers can be applied to PV modules acting as both anti-reflective as well as self-cleaning top covers. The Figure at the left shows a SEM image of a structured fluorinated polymer surface. At IMT we investigate this possibility using bio-inspired patterns replicated via advanced hot-embossing techniques.

Contact: U. Paetzold

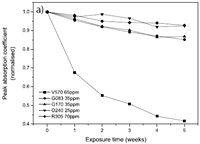

Every concept/technology that has the potential for application to PV modules has to withstand the long-term exposure to the environment that a PV module is destined to endure during its lifetime. At IMT we test the materials/layers/coatings/devices we investigate for stability under a range of parameters, including UV, humidity, temperature cycling and combinations thereof. The Figure at the left shows the degradation of organic luminescent dyes under accelerated exposure to UV light.

Contact: U. Paetzold