Microstructures and Process Sensors (MPS)

Prof. Dr. Jürgen J. Brandner [Contact]

Welcome

...to the webpage of the Microsystems and Process Sensors group.

The MPS group’s research is focused on materials and designs for advanced microsystems in visualization and measurement of (bio-) chemical processes. From design, simulation and modeling of devices to manufacturing using the latest technologies to applications in in-situ and operando mode is covered. For manufacturing, 3D printing of various materials, ranging from polymers to glass and ceramics, and from millimeter to nanometer range, is performed.

Our research contributes to the research program 3: "Materials Systems Engineering" (MSE), Topic 5: "Materials Information Discovery", in the research field „Information“ as defined by the Helmholtz Association (link to MSE website). Aim is to enhance knowledge on existing materials and develop new, taylor-made material systems by correlative analytical and design approaches.

Additionally, we are in major European and DFG-funded projects.

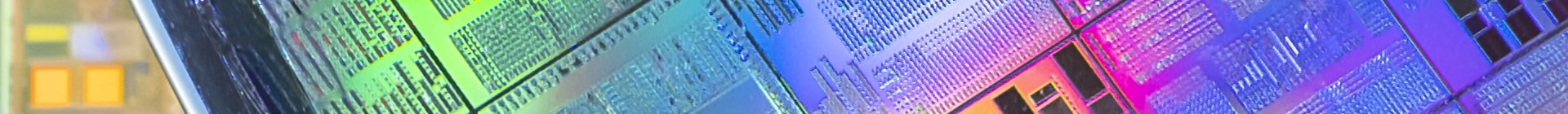

Figure: Several projects of the MPS group. Flow-through fluorescence sensor (left), 3D-printed alumina parts (upper middle and right), high precision 3D printed polymer nozzle (lower middle), 3D design of a multi-layer device (lower right).

Subject areas

Our research focuses on multi-scale devices and (functionalized) materials for correlated manufacturing and measurement technologies, combined with research data management RDM. We aim for applications in biology, chemistry and related topics, trying to realize as often as possible in-situ and operando applications to retrieve the most authentical information possible. Thus, the materials used are wide-span, to cover a large area of pressure (high vacuum to several ten bar), temperature (from cryogenic up to several hundred K) and fluids (gases like hydrogen or noble gases, liquid fluids from organic liquids in biology to highly corrosive liquids or particle–loaden liquid systems. We are using single phase and multi-phase systems.

Standard sensors (pressure, temperature, mass flow) ae similarily used as Nuclear Magnetic Resonance spectroscopy (NMR) and imaging (MRI); other kinds of visualization like high-speed optical or IR cams as well as µCT and 3D scan systems. To increase sensitivity, we employ hyperpolarization techniques based on parahydrogen for NMR and MRI. Within seconds, signals are generated that are many orders of magnitude higher than those afforded in standard. Here, we closely co-operate with the Lehmkuhl group Hyperpolarisation HYP and other partners within the CRC 1527 – HyPERiON.

Materials and devices for multi-scale research and appliations

Many research topics and – lateron – applications need specific materials and devices with multiscale functionalities. We realize such devices from scratch, starting with modelling, simulation and 3D CAD design. As a next step, material choice or development takes place depending on the desired process parameters. Finally, devices are generated, meanwhile preferably by 3D printing. However, other technologies are highly welcome.

Fundamental research

We investigate fundamental phenomena of different kind, ranging from the behavior of cryogenic compressor systems (within PuCK, HOMER and CRC HyPERiON projects (Link), to the RASER in NMR, fully automated lab systems, integration of process chemistry into NMR systems or investigation of microfluidic phenomena with visualization techniques like MRI (Link). A lot of our research work is supported by KNMFi, one of the large Research Infrastructures within KIT.

In co-operation between the HYP and MPS groups, J. Yang and S. Lehmkuhl published a paper on the steady-state ALTADENA RASER, including the title view of the magazine.

In co-operation between the SMS and MPS groups, A. Hurtado, J. Schulte-Hermann and J. Yang published a review paper on Integrating Micro Process Chemistry into an NMR Spectrometer.

Dr. Georges Saliba published a Letter in „Physics of Fluids“ on Magnetic Resonance Velocimetry to reveal secondary flows in Micro Falling Film reactors.

For her project within the EC-ITN MIGRATE, IMT PhD student Sofia Toto received the IUVSTA-Elsevier Student Award at the 15th European Vacuum Conference in Geneva (Switzerland).