Low-cost MEMS (LCM)

Dr. Dario Mager [Contact]

Welcome

... to the low-cost MEMS group. We focus on developing non-conventional microtechnology that is not dependent on expensive high-quality cleanrooms. These components can naturally often not compete with the performance of standard cleanroom MEMS devices. To compensate that drawback, we use embedded systems that digitally compensates, for example, a fairly big variation among the devices. Beside that we also explore less complicated fabrication routes like glassy carbon.

Our research contributes to the research program 3: "Materials Systems Engineering" (MSE), Topic 5: "Materials Information Discovery", in the research field „Information“ as defined by the Helmholtz Association. Link to MSE website.

Subject areas

System development is not specific to a certain research area and we apply it to many fields.

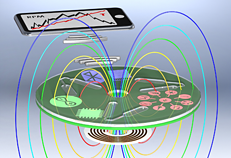

Improving state of the art scientific equipment with custom-made add-ons

One of the major research topics at IMT is magnetic resonance (MR) which is based on very strong yet very precise machines. These machines can be bought for a significant amount of money, and they fulfill their desired purpose of giving information about the chemical composition of a sample. However, with custom-made add-ons we improve the user-experience significantly, either by automating them, or improving the signal quality for specially shaped sample containers, to mention two applications.

Matching the cost structure to the application using DIY technology

Scientific equipment is often very expensive, that comes partially because of the precision needed, but mainly because of the low numbers of devices fabricated, that leads to high development costs and devices that are fairly generic and only optimized to the best signal quality. Using existing embedded system and consumer electronics, one can design devices that fulfill a certain purpose at a fraction of the cost of conventional lab equipment. Also, when a technology should leave the lab and be converted into a product its legacy of being based on expensive lab equipment can come as a burden. In the area of centrifugal microfluidic testing we have, e.g. implemented a completely consumer electronic based centrifugal microfluidic framework (the reLoaD) that is comparable with conventional setups existing in research labs, but it comes at a fraction of a cost. The system is also designed as an open-hardware project, even further lowering the entrance barrier for research groups situated in areas where centrifugal diagnostic is intended for.

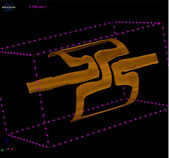

Material for low-cost MEMS

Conventional cleanrooms are the realm of crystalline semiconductor materials like Si or GaAs, that are complicated to process. In our group we focus more on glassy carbon as structural material since it can be structured with a fairly simple route of structuring a polymeric precurser with lithography or stereolithography and then converting these structures via pyrolysis into glassy carbon. This technology nicely supports our approach on the material side.

Lab to Market

We also apply the idea of using consumer electronics for other purposes in our teaching. So far two student teams managed to convert their ideas using embedded system into products and found their own companies.

|

|

|