High field compact super conducting magnets (HCM)

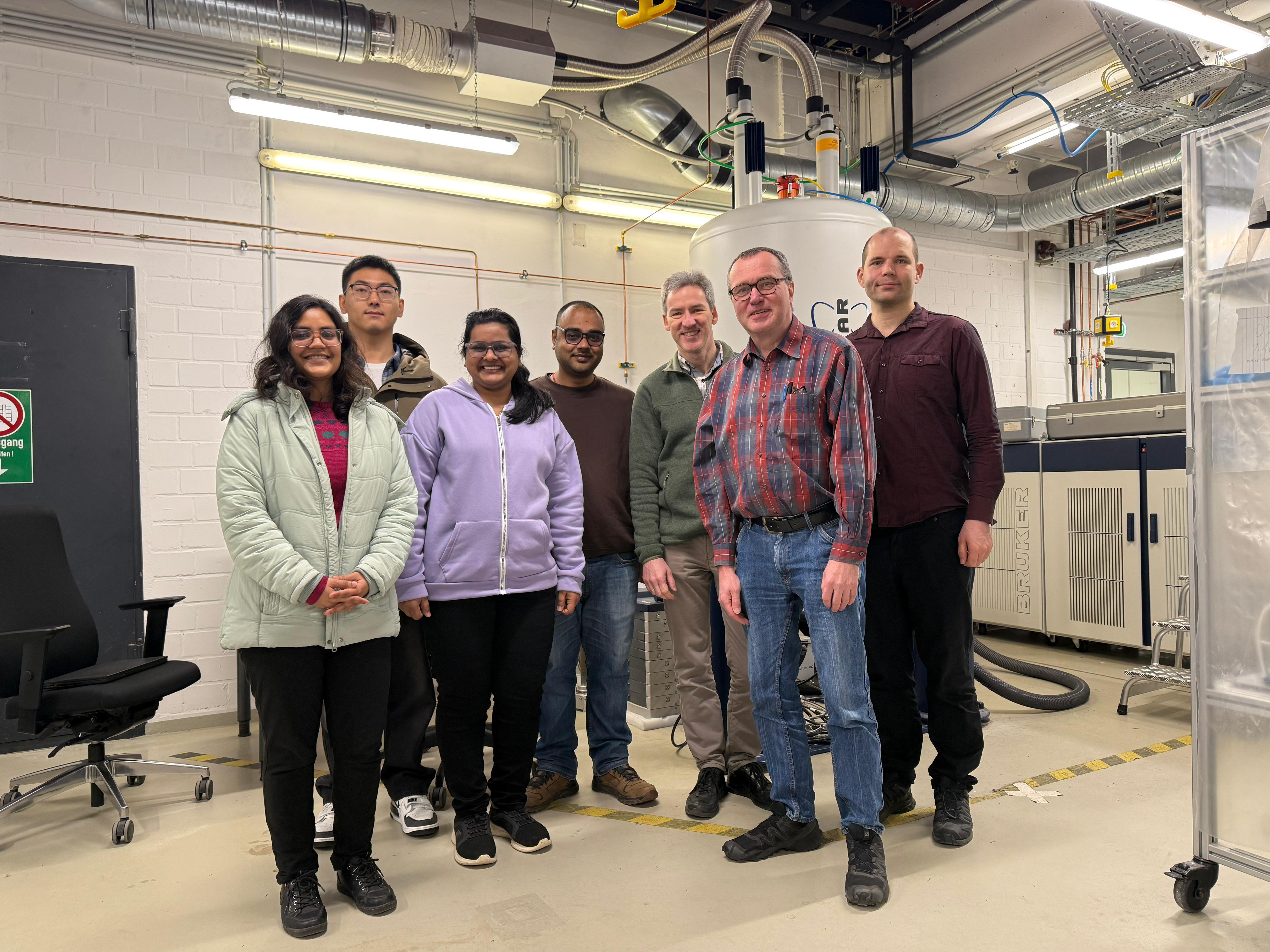

PI Dr. Martin Börner [Contact]

Welcome

...to the webpage of the high field super conducting magnets (HCM) group.

In our group we are going to improve the properties of superconducting material in terms of stability, higher critical temperatures and ampacity by introducing “nanodefects”. We are convinced that this will enable us to miniaturize and enhance NMR systems, paving the way for introducing these techniques in everyday applications, not only in areas like biomedicine and chemical industry, but also in power engineering (one of our biggest questions these days), digitalisation, and so on. This broader range of applications will be a breakthrough for mankind. Here, we closely co-operate with ITEP of KIT (Institute of technical physics) and other partners within the CRC 1527 – HyPERiON

Our research contributes to the research program 3: "Materials Systems Engineering" (MSE), Topic 5: "Materials Information Discovery", in the research field „Information“ as defined by the Helmholtz Association. Link to MSE website.

Together with Jan Korvink, Mazin Jouda, and Jürgen Brandner from IMT, and my colleagues Tabea Arndt, Bernhard Holzapfel, and Jens Hänisch at ITEP, we want to advance the science and engineering of compact high field NMR magnets. We believe that it must be possible to build quality NMR magnets in a small space, around the size of a milk bucket or a cooking gas cylinder, something that could be positioned unobtrusively on a laboratory benchtop. The availability of such magnets would radically simplify access to quality NMR analysis. For example, it would be possible to incorporate the magnets in chemical plants, or semiconductor factories, or in food processing equipment. Research laboratories would benefit from excellent spectroscopy in affordable and space-saving equipment, and ultra-high field magnets would also benefit from this more compact arrangement to form their core. I am convinced that, if we are successful, many other non-NMR magnet applications will also benefit, such as accelerator beam benders, current generators, motors, and transformers, instruments such as mass spectrometers, and other high current electrical equipment. The interdisciplinary nature of this project requires a diverse team with a variety of skills. PhD students Shraddha Singhal and Sukanya Baruah are tackling an important aspect of our research project:

The main motivation of our project is to produce superconducting thin films e.g. by using the pulsed-laser deposition method, characterize these films and introduce artificial pinning centres and defects necessary for very strong, homogeneous and stable magnetic fields, using self-assembly techniques. With the help of nano-fabrication and micro-structuring techniques, we plan to employ different magnet topologies to assemble a powerful superconducting magnet that will help us build a desktop-like NMR device in the high field range that is compatible with a wide range of applications in the fields of material science, food science, biology, chemistry, medicine etc.

The team also collaborates with two IMT colleagues whose projects link to our own – Mazin Jouda’s with regard to shimming, and Jürgen Brandner’s with regard to the cooling of magnets. While we are working towards making a first magnet, we consult them from time to time, and we hope to incorporate their technology one day.