Large Scale Surface Structuring by Micro and Nanoreplication Processes (LSS)

Welcome

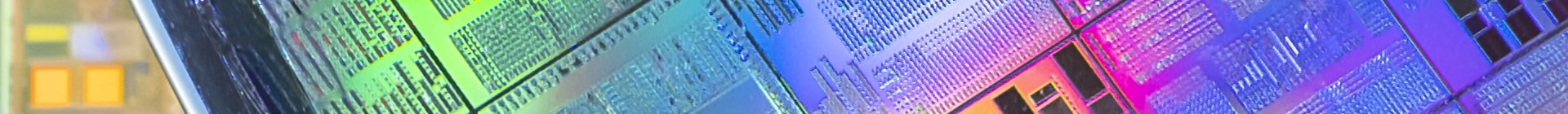

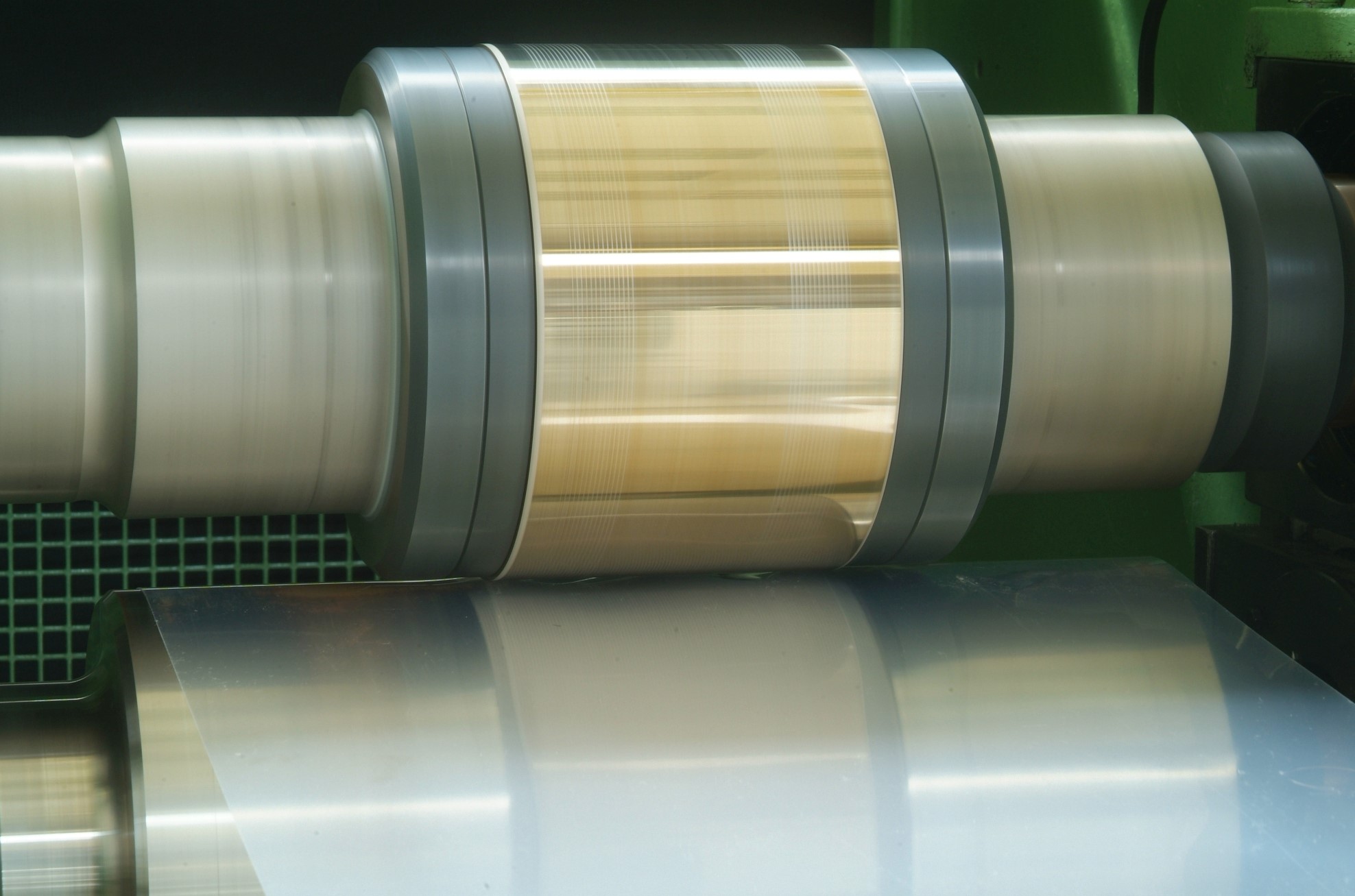

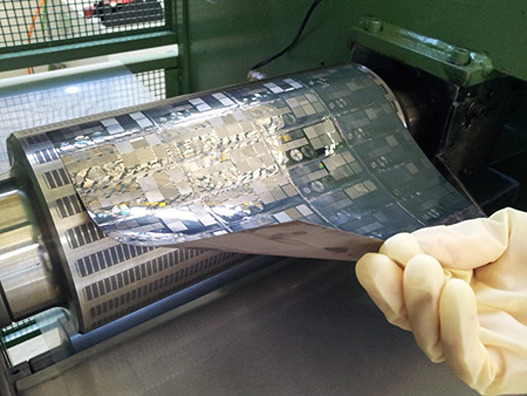

The focus of our research is set to the development of cost efficient and scalable surface structuring processes, performed .in batch processes at wafer scale by hot embossing, nanoimprint and thermoforming. Beyond wafer-scale and typical areas of (3D)-printing an upscaling of the structured area can efficiently be achieved by seamless roll-to-roll processing. For this so-called large scale structuring we use a high pressure calender and extrusion flat film lines.

An advantage of this processing is the technical flexibility and the diversity of materials. In batch process beside the class of standard, technical, and high performance thermoplastics also materials like nanocomposites, metallic glasses, or soft metals are processible. A focus is set to the class of shape memory polymers allowing the generation of so-called smart surfaces with a switch of surface properties by an external trigger. This material allows further the replication of 3D micro- and nanostructures structures, currently the domain of 3D printing.

Cooperation and Applications

Currently our work is embedded in the Helmholtz program of Energy (MTET, subtopic 3 and 4) with focus on the increase of efficiency of solar panels by surface structuring and the encapsulation of (tandem) Perovskite solar cells. Link

Further the replication of 3D optical components and their precise alignment by a developed replicable modular system is embedded in the Helmholtz program of Information, in particular in Materials systems engineering (Topic 2, subtopic 3 -Designed Optical Devices and Systems) . Link

Biomimetic superhydrophobic surfaces, especially fabricated by the process of hot pulling of fine hairs (so-called nanofur) for water-oil separation is developed in cooperation with Prof. Hölscher at IMT. Link

Due to the structuring of thin films, the process of hot embossing is well suited for microfluidic applications. Currently we fabricate specific microfluidic samples for NMR analysis correlated with Prof. Marcel Utz within the Helmholtz program Information. Link

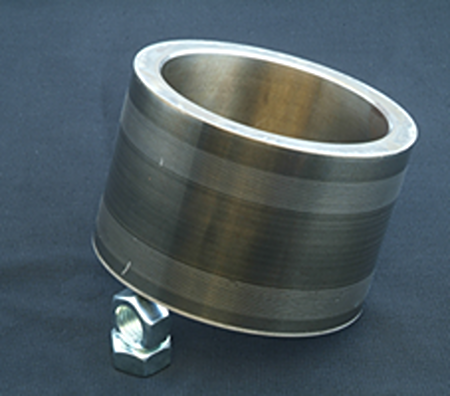

All replication processes typically requires a high quality mold or so-called mold insert. The technology of electroplating transfers the structures from a lithographic master to a Nickel mold insert. The different technology specific mold inserts are developed and processed within the group of Dr. Markus Guttmann. Link

Finally, our processes and support is also available for external user by the KNMFi – the Karlsruhe Nano Micro Facility for Information-driven Material Structuring and Characterisation.

Seamless roll-to-roll replication of microstructures in thermoplastic polymer film using a structured sleeve

Seamless roll-to-roll replication of microstructures in thermoplastic polymer film using a structured sleeve

Seamless R2R

Development of a process chain for seamless micro replication using a structured sleeve. The chain consists of a controlled sleeve processing, starting with resist coating, UV-lithography, and development. The electroplating starts directly from the ground of the sleeve and after resist stripping the sleeve is mounted in a calender for film structuring. Alternative but with seams we use large scale electroplated Nickel shims wrapped around a magnetic roll.

|

|

Literature: A. Striegel, M. Schneider, N. Schneider, C. Benkel, and M. Worgull, “Seamless tool fabrication for Roll-to-Roll microreplication,” Microelectronic Engineering, vol. 194, pp. 8–14, 2018, doi: link

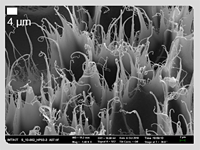

Hot pulling

Hot pulling is a scalable molding technique for the fabrication of high aspect ratio nanohair allowing the cost efficient fabrication of miscellaneous biomimetic functional surfaces. In this modified hot embossing process, fine hairs were pulled from a polymer melt. As mold insert a structured tool or even a sandblasted steel-plate can be used. The resulting nanofur (in cooperation with Hendrik Hölscher) is superhydrophobic and suitable for various applications inspired by Lotus leaves, rose petals, pitcherplants and the floating water fern Salvinia

|

|

- Literature: Michael Röhrig, Matthias Mail, Marc Schneider, Henri Louvin, Andreas Hopf, Thomas Schimmel, Matthias Worgull, and Hendrik Hölscher. Nanofur for biomimetic applications. Adv. Mater. Interfaces, 1:1300083 (10pp), 2014.

- M. Röhrig, Marc Schneider, G. Etienne, F. Oulhadj, F. Pfannes, A. Kolew, M. Worgull, and H. Hölscher. Hot pulling and embossing of hierarchical nano- and micro-structures. J. Micromech. Microeng., 23:105014 (7pp), 2013

Hot Embossing – Theory of Microreplication – M. Worgull, Hot Embossing, 2 ed., 638p, Elsevier, 2024, Paperback ISBN: 9780128211939 eBook ISBN: 9780323984218.

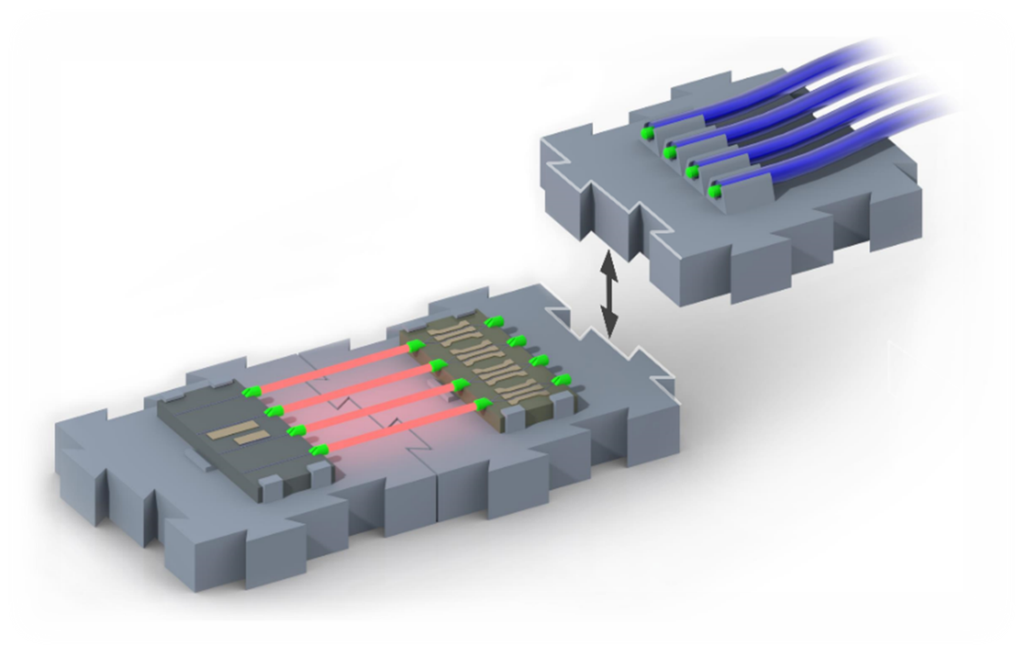

Pluggable Single-Mode Chip-Chip Connections Using Facet-Attached Microlenses and Passive Mechanical Joints