Manfred Kohl received his Ph.D. in physics from the University of Stuttgart, Germany. He worked as an IBM postdoctoral fellow at the T.J. Watson Research Center in Yorktown Heights, USA, and subsequently joined the Karlsruhe Institute of Technology (KIT), Germany. He is currently a professor at the Faculty of Mechanical Engineering and Head of the Department of Smart Materials and Devices at the Institute of Microstructure Technology of KIT. He is co-organizer of the International Conference and Exhibition on New Actuator Systems and Applications and coordinator of the Priority Program KOMMMA (Cooperative Multistage Multistable Microactuator Systems) of the German Science Foundation. His current research focuses on ferroelastic and ferromagnetic shape memory alloys, multimaterial micro- and nanotechnologies as well as corresponding smart devices.

Research Areas

Department Smart Materials and Devices (SMD)

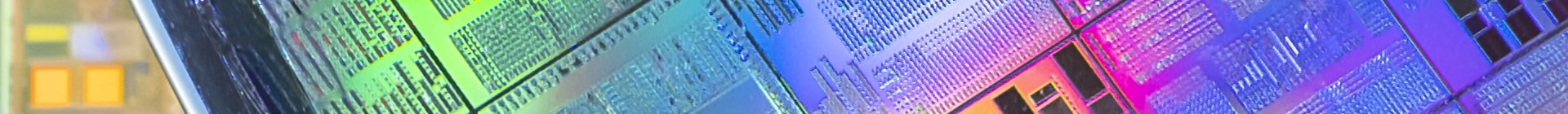

Smart materials are characterized by their multifunctional properties, in particular, sensing and actuation functions. Important examples are shape memory alloys (SMAs), piezoelectrics, as well as multiferroic materials. These materials show large abrupt changes of their physical properties near phase transformations allowing for compact device actuator and sensor designs. Therefore, they are predestined for applications on the micro- and nanometer scale.

Our research contributes to the research program 3: "Materials Systems Engineering" (MSE), Topic 1: "Functionality by Information-Guided Design: From Molecular Concepts to Materials", in the research field „Information“ as defined by the Helmholtz Association.

Link to MSE website

Overview of Smart Materials and Devices (SMD)

Group 1: Microactuator Systems (MAS), M. Kohl

We combine smart materials, micro engineering and micro/nano technologies to develop novel smart actuators, sensors and multifunctional devices. In the focus are shape memory alloys that can be reversibly deformed by strain values exceeding 10% and still recover their original shape by heating (thermal shape memory effect) or by applying a magnetic field (magnetic shape memory effect). Based on these materials we develop multilayer material systems and corresponding device architectures at the micro- and nanometer scale with actuation and self-sensing capability.

Link to MAS Website

Group 2: Thermomagnetische Mikroaktoren und Generatoren (TMG), J. Joseph

Smart materials are useful to convert waste heat or vibrational energy into electricity (energy harvesting).

Group 3: Zero-emission and eco-friedly heating and cooling technologies (ZET), J. Xu

Another important topic is solid-state cooling. Shape memory alloys show very large changes of latent heat in the order of 20 J/g that are exploited for cooling and heat pumping applications.

Lectures

| Title | Semester | Lecturer |

|---|---|---|

| Anleitung zum wissenschaftlichen Arbeiten | WS and SS | M. Kohl |

| Microactuators | SS | M. Kohl |

| Aktuelle Arbeiten auf dem Gebiet Mikrosystemtechnik "IMT Seminar" | WS and SS | M. Kohl |

| Novel actuators and sensors | WS | M. Kohl |

More details under: Lectures

DFG Priority Programs

|

FerroicCooling | SPP 1599 |

|

Calm, Smooth and Smart | SPP 1897 |

|

Cooperative Multilevel Multistable Micro Actuator Systems (KOMMMA) We are coordinating the DFG Priority Program “KOMMMA”, which bundles the research of 18 Principal Investigators over 6 years. Objectives of this interdisciplinary program are to show up new methods and concepts to understand the complex coupling and synergy effects in coupled microactuator systems as well as to fabricate platforms for cooperative and/or multistage microactuator systems. |

SPP 2206 |

Start-up

|

memetis website |

Publications

Selected publications are listed here.

Further information can be found at: Scholar