Hot pulling of Nanohairs

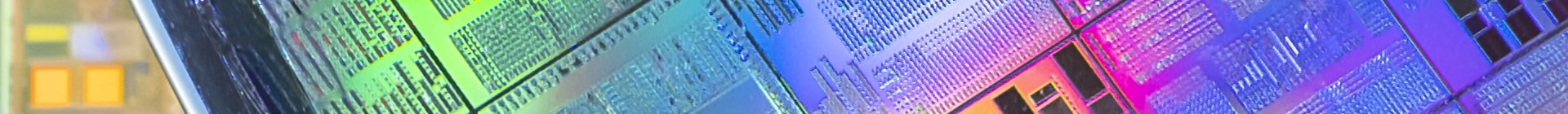

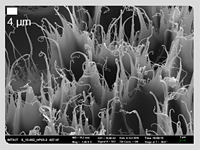

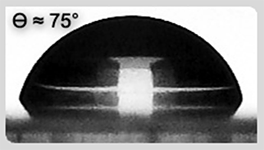

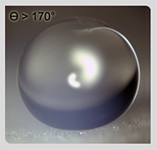

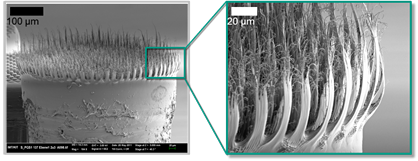

Hot pulling is a scalable molding technique for the fabrication of high aspect ratio nanohair allowing the cost efficient fabrication of miscellaneous biomimetic functional surfaces. In this modified hot embossing process, fine hairs were pulled from a polymer melt. As mold insert a structured tool or even a sandblasted steel-plate can be used. The resulting nanofur (in cooperation with Hendrik Hölscher) is superhydrophobic and suitable for various applications inspired by Lotus leaves, rose petals, pitcherplants and the floating water fern Salvinia.

Hot Pulling of nanofur

|

|

|

||

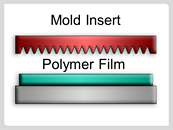

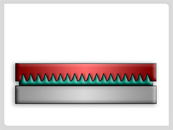

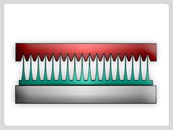

| Scheme of the Hot pulling process – a mold is pressed into a polymer melt and fine hairs will be achieved by a controlled pulling step. |

||||

|

|

|

||

| Nanohairs “Nanofur” change the wetting properties of polymer surfaces to superhydrophobic state. |

||||

|

|

|

||

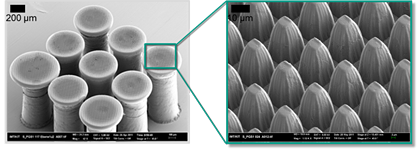

| Combination of hot pulling with hierarchical structuring by hot embossing: In first step the structures of level 1 are replicated by hot embossing. In a second step smaller structures were embossed on top of the structures obtained in step 1. Finally in a third process step fine fine hairs with tips in the range of around 200nm will be pulled from the structures obtained in step 2. |

||||

|

| Hierarchical Structuring by hot embossing |

Literature

- Michael Röhrig, Matthias Mail, Marc Schneider, Henri Louvin, Andreas Hopf, Thomas Schimmel, Matthias Worgull, and Hendrik Hölscher. Nanofur for biomimetic applications. Adv. Mater. Interfaces, 1:1300083 (10pp), 2014.

- M. Röhrig, Marc Schneider, G. Etienne, F. Oulhadj, F. Pfannes, A. Kolew, M. Worgull, and H. Hölscher. Hot pulling and embossing of hierarchical nano- and micro-structures. J. Micromech. Microeng., 23:105014 (7pp), 2013