High speed miniaturized rotary turbo-machinery for scientific instruments applications

- Type:Master Thesis

- Supervisor:

- Field of Study:

Mechanical and/or electrical engineering, MEMS

Job description

Rotating micro-machinery is commonly used for various energy conversion applications. Motors and turbines convert electrical or fluid power into mechanical power, with high peripheral speeds being desirable.

The central topic of this Master thesis is the miniaturization of high-speed turbomachinery for applications in specific scientific instruments. This task imposes specific challenges: careful design of millimeter and sub-millimeter scale blades, integration of various types of bearings, simulation of the fluid dynamics within the devices. All these challenges must consider micrometer scale tolerances for robust and precise operation.

Are you passionate about mechanical engineering? Are you ready to challenge yourself in developing the fastest miniaturized turbine as the goal of your Master thesis? Are you interested to solve interesting design problems related to the development of microscale rotary turbomachinery? Do you have the ambition to fabricate and test the micro-turbine while spinning at record speeds?

If “yes”, we are looking for you!

The specific tasks within the project will be: (i) decide on the micro-turbine actuation type, e.g., electrostatic, fluid; (ii) micro-turbine design and fabrication; (iii) micro-turbine testing. During the Master thesis, you will get hands-on experience on microsystems design, cleanroom fabrication, micro-structural characterization, having the opportunity to get exposure to a wide range of instruments and techniques.

You will be integrated in the larger team of the Spin & Photon Applications (SPA-) Laboratory. Within this project, you will use the infrastructure existent at the Institute of Microstructure Technology (IMT), i.e., microfabrication facilities and micro-characterization equipment. This is a complete project, offering the possibility to fabricate and test the devices, giving you the opportunity to co-author conference and/or journal publications.

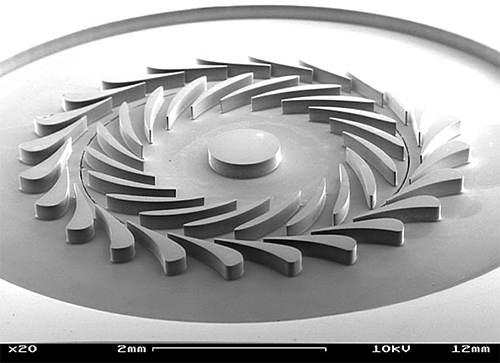

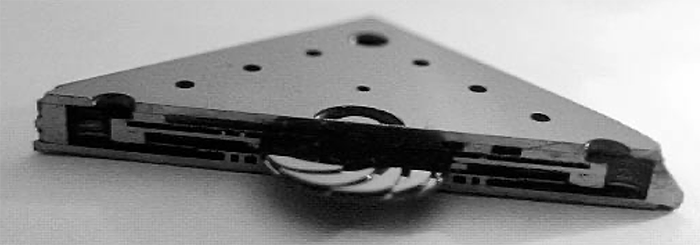

Figure 1. The MIT gas turbine: LEFT: 4 mm rotor radial inflow turbine; RIGHT: cross-section of the demo gas turbine [A.H. Epstein, Millimeter-scale, MEMS gas turbine engines, Proceedings of ASME Turbo Expo 2003, Power for Land, Sea, and Air June 16-19, 2003, Atlanta, Georgia, USA]

Starting date: by appointment

Contract duration: 6-9 months

Qualification:

- good academic record (marks); curious about various aspects of science;

- enthusiastic to work in a multidisciplinary environment;

- independent thinker and team player;

- in particular: strong interest in mechanical engineering and microsystems technologies;

- knowledge in microsystems/microfabrication is desirable.

Technical Contact

Dr. Vlad Badilita

Karlsruhe Institute of Technology

Institute of Microstructure Technology

P.O. Box 3640

76021 Karlsruhe

phone: +49 721 608-29315

e-mail: vlad badilita ∂does-not-exist.kit edu