Microvalves

Monostable Shape Memory Alloy Microvalves

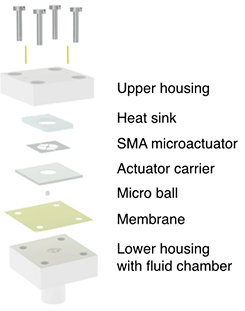

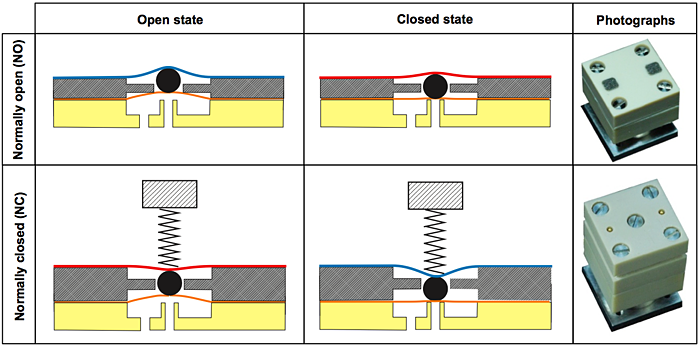

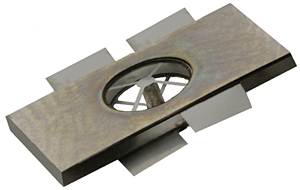

Shape Memory Alloy (SMA) microvalves comprise a polymer housing with an integrated fluid chamber, membrane, and SMA microactuator. The microactuator is deflected by a plunger, e.g., a microball. At zero current, the microvalve is in open state. In this case, the fluid is able to flow through the valve, if a supply pressure is present. By electrical heating, the microactuator changes to its planar shape memory state and thereby closes the microvalve.

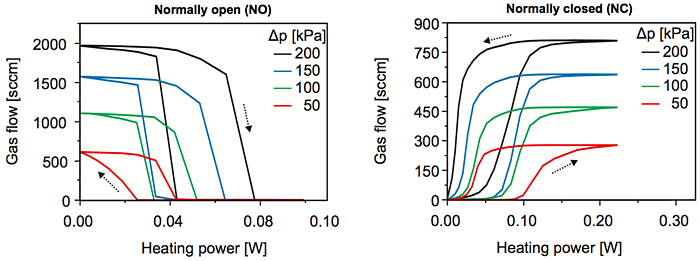

Monostable microvalves close and open in power-off condition and by electrical heating, respectively. In order to enable a compact design at preferably high fluidic power, a micro-machined SMA foil is used for actuation. Monostable microvalves are designed in a modular way to reduce the number of components. This enables economic fabrication of normally-open (NO) and normally-closed (NC) microvalves as well as fast adjustment to required pressure and flow range.

For dosing applications and pressure-independent flow control, the system is extended by a flow sensor and closed-loop control.

|

Performance Characteristics

|

|

|

|

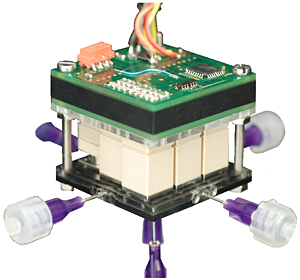

Fluidic control system

The fluidic control system consists of up to nine SMA microvalves, electrical circuit, and fluidic backplane. The microvalves are attached to the fluidic backplane by a reversible magnetic plug-in interface. The system enables guiding and regulation of gases and liquid flows.

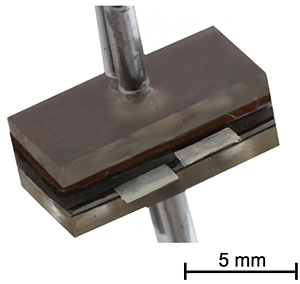

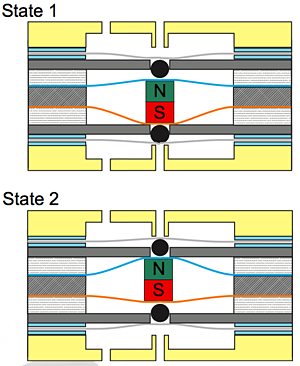

Bistable Shape Memory Alloy Microvalves

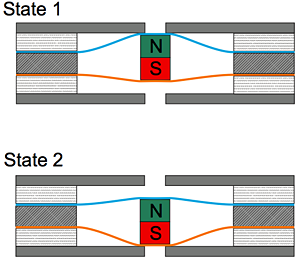

Bistable Shape Memory Alloy (SMA) microvalves only consume energy during switching and, thus, are suitable for fluidic systems operating at low average power consumption and low duty cycles.

Bidirectional actuation is realized by two counteracting and selectively heated SMA microbridge actuators. In power-off condition the stable positions are held by magnetostatic latching forces..

|

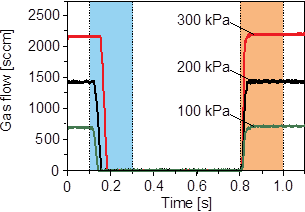

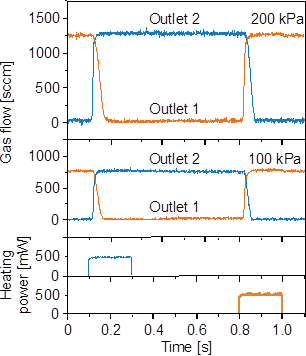

Performance Characteristics

|

|

|

|

|

|

|

|

|

Detailed view of a microactuator of NiTi, which is opening and closing a membrane microvalve. Download video: MP4 format, 3.3 MB |

Further information:

- T. Grund, C. Megnin, J. Barth and M. Kohl, Batch fabrication of shape memory actuated polymer microvalves by transfer bonding techniques, The Journal of Microelectronics and Electronic Packaging 6, (2009) 219-227.

- J. Barth, B. Krevet and M. Kohl, A bistable shape memory microswitch with high energy density, Smart Mater. Struc. 19, (2010) 094004.

- J. Barth, C. Megnin, M. Kohl, A Bistable Shape Memory Alloy Microvalve With Magnetostatic Latches, Journal of Microelectromechanical Systems 21, (2012) 76-84

- M. Brammer, C. Megnin, A. Voigt, M. Kohl, and T. Mappes, Modular Optoelectronic Microfluidic Backplane for Fluid Analysis Systems, Journal of Microelectromechanical Systems 22, (2013) 462-470

- C. Megnin, and M. Kohl, Shape Memory Alloy Microvalves for a Fluidic Control System, Journal of Micromechanics and Microengineering 24, (2014) 025001